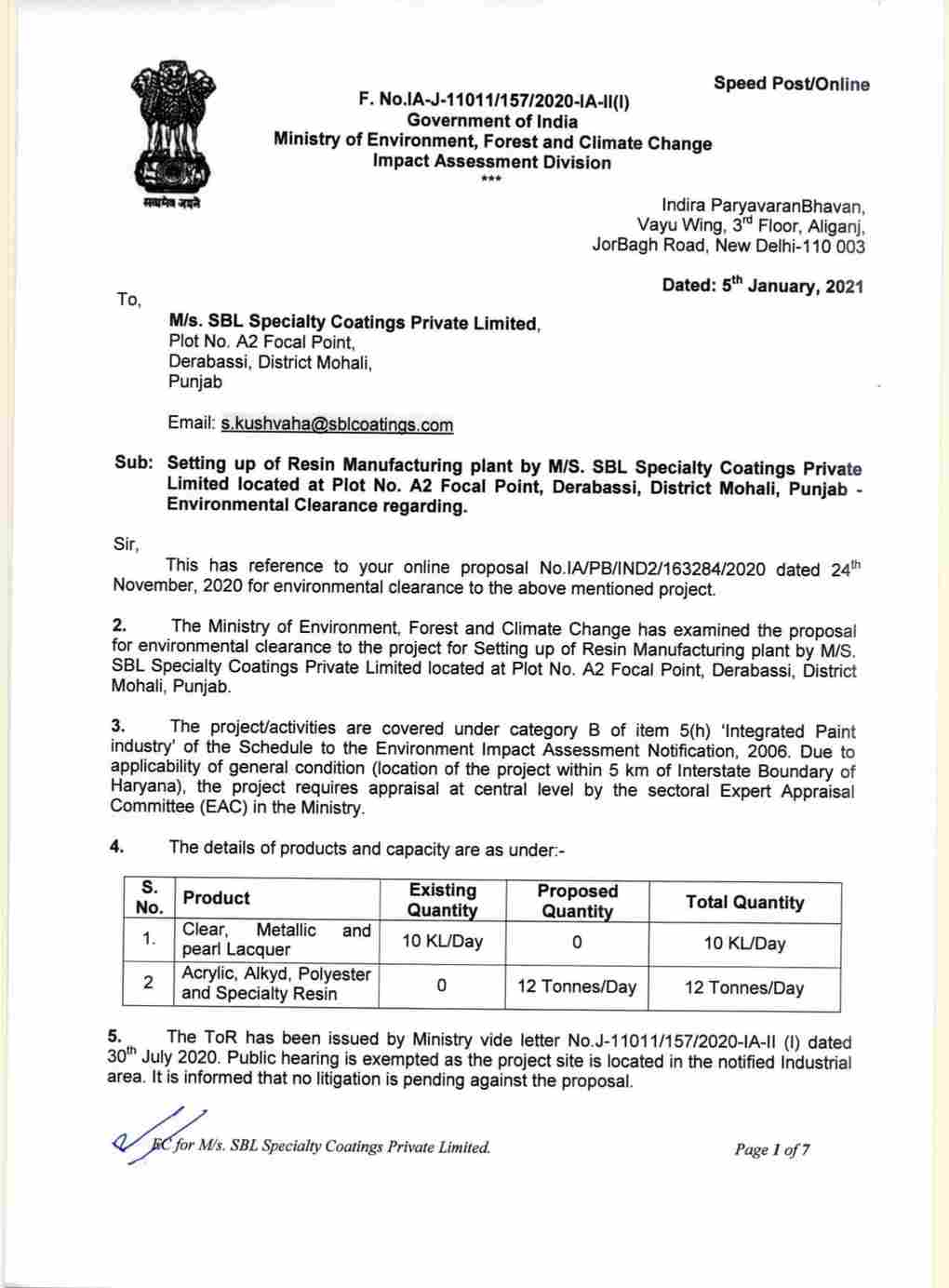

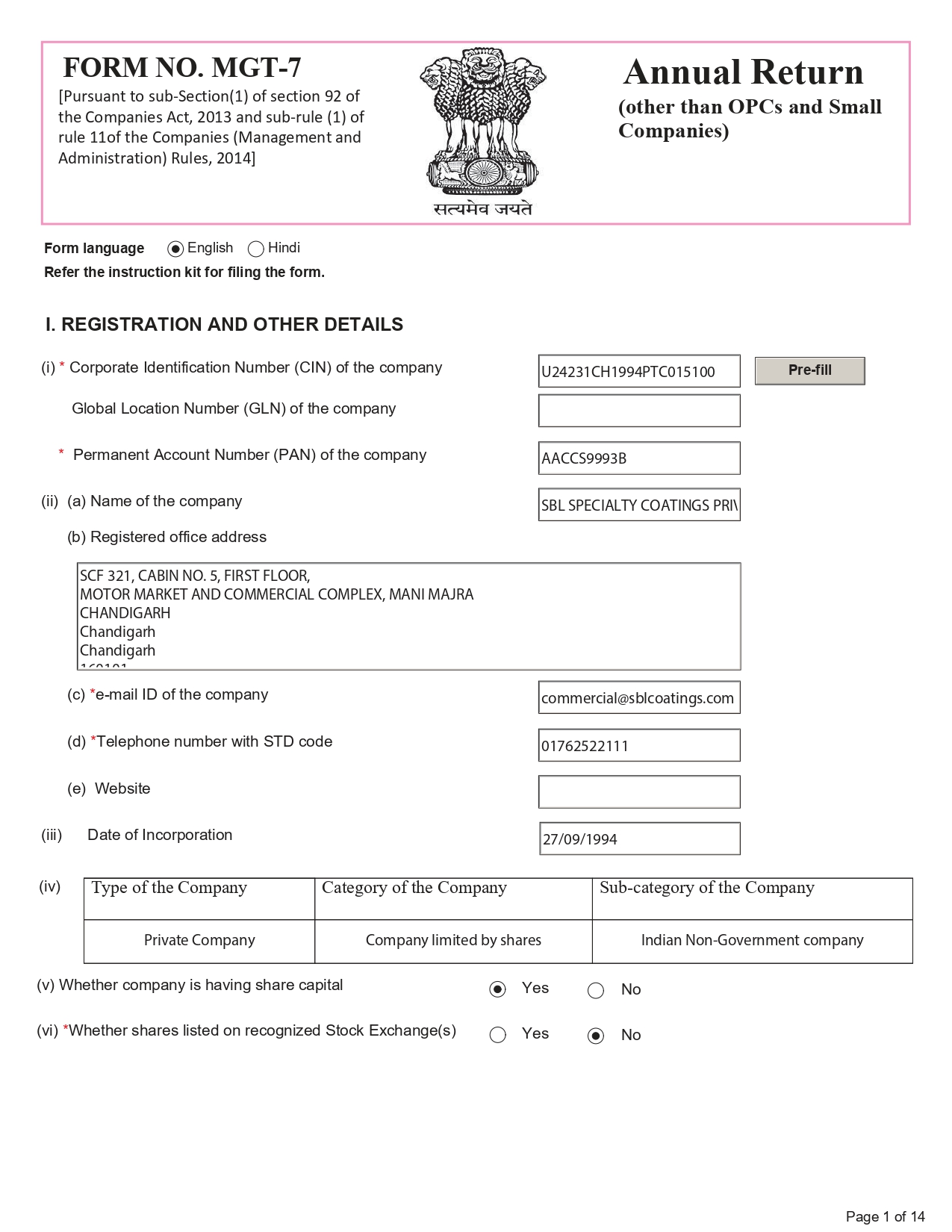

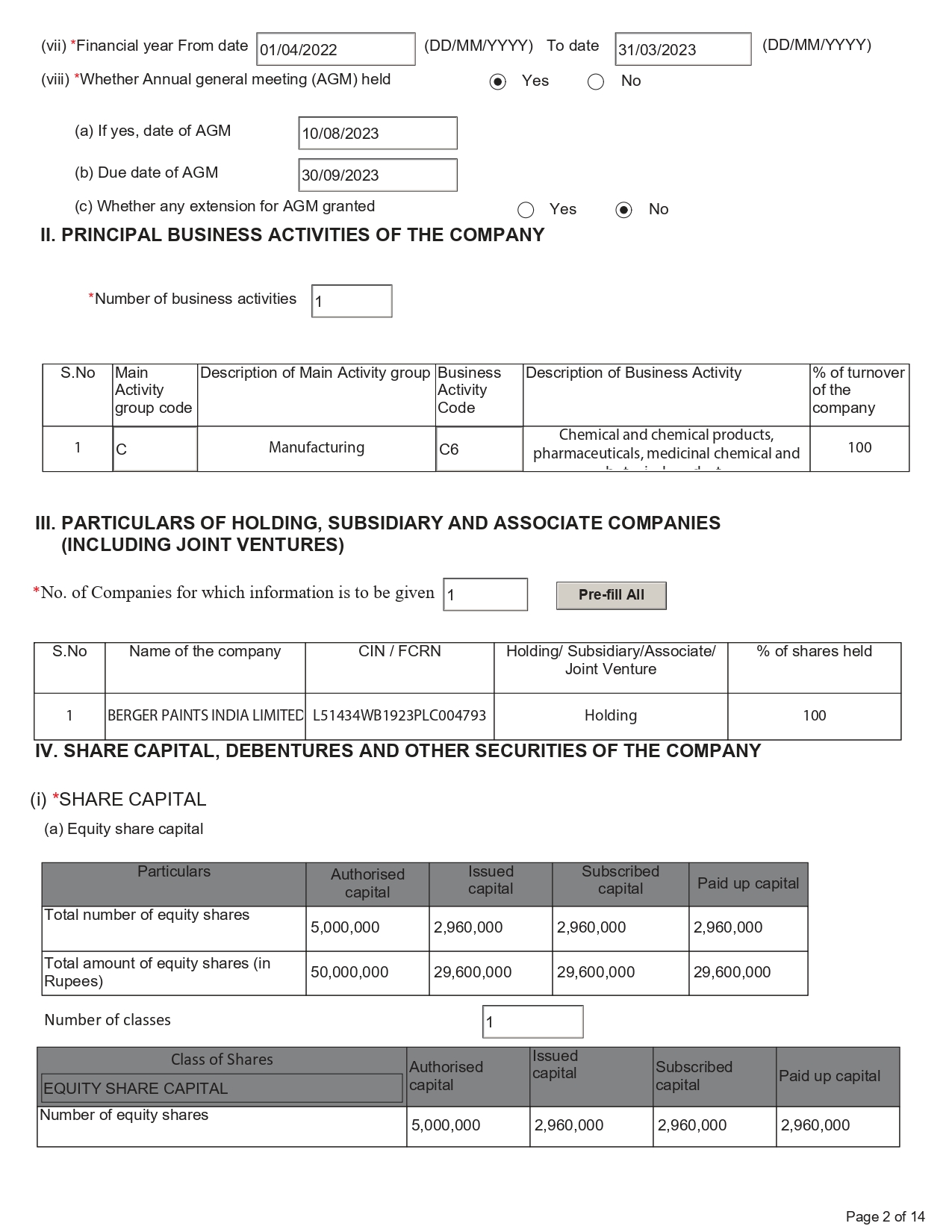

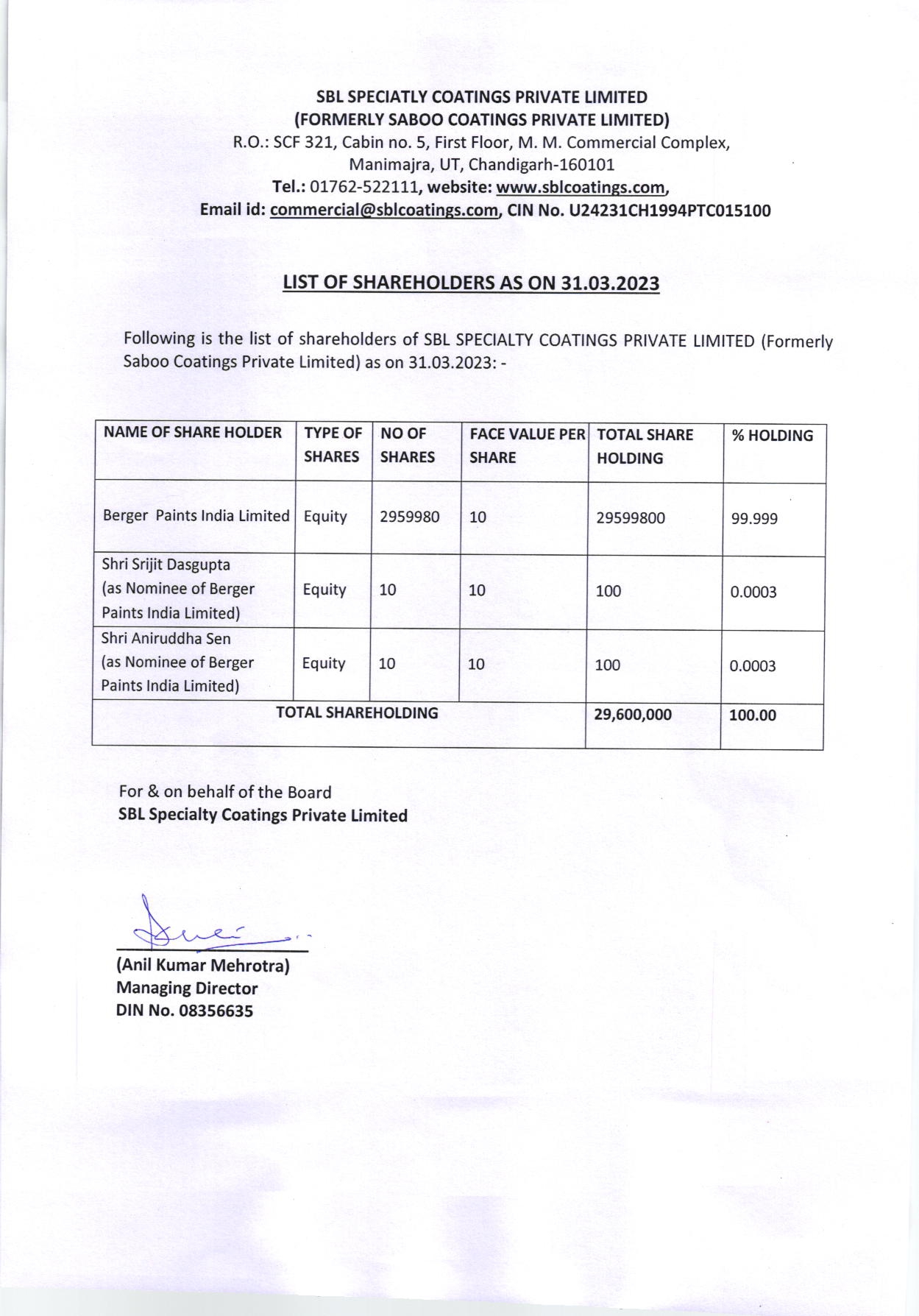

SBL Specialty Coatings Private Limited, a 100% subsidiary of Berger Paints India Limited (an Indian MNC rated the 2nd largest Paint Company in India and amongst the top 15 Paint companies of the world) manufactures Specialty Industrial Coatings formulated by leveraging Swiss technology and having manufacturing plants located in Derabassi (Punjab).

SBL Magico is a revolutionary product in the Specialty Coatings Industry, which is a one-stop solution for your various painting needs. You can use it on any surface or substrate, whether Aluminium, Glass, Brass, Copper, Wood and many more. Indeed, the newly launched Magico is an excellent result of the companys state-of-the-art R&D.

Extremely Progressive

With wide distribution channels, sales and support offices spread across India, SBL holds the distinction of being the fastest growing company in the domain of Specialty Coatings. Strengths like Superfast Response time, Customized Products, Dedicated Sales team and Strong R&D team further helps it to be the Industry leader. With credible experience in coatings technology, our R&D team work religiously to Customize and Optimize our existing products for Quality and Cost-competence. The company offers a robust range of products like Primers, Putty, Base Coats and Top Coats in various visual effects like Pearl, Metallic, Opaque and Clears in Custom-made finishes. The range of products are available in assorted chemistries like Polyurethanes, Epoxies, TSA, TPA, Silicones, Alkyds in Water based, Solvent Based, UV cured and Electrocoatings.

Suitable for multiple industries

The company has its own resin plant for it captive consumption, which helps in developing Custom, made products as per the quality and application specifications of the clients in assorted segments. Prominent industries include elevator, handicraft, fan, washing machine, electrical appliance, glass, hardware’s, security solutions, furniture, textile accessories and many more.

International Quality Compliance

We are an ISO 9001:2015 certified company, run by a team of veterans from the coating industry. We strictly adhere to the international quality standards and keep our processes detailed to deliver industry best products. We source raw material from trustworthy suppliers and use rigorous production method followed by double QA to ensure consistency in our product quality.

Bottom Line

SBL is beyond doubt, the fastest growing company in the specialty coating domain. Its board of directors ensures strong corporate governance in every aspect, i.e., from sourcing raw material to production, testing to product launch and in further innovation. No wonder, it specializes in tailor-made solutions, finishes & visual effects like no one else in the industry. This ISO 9001:2015 certified company continues to amaze the customers owing with its cutting edge products; SBL Magico being the latest one.

Purpose

To Be A Stakeholders Delight.

Vision

To be the Most Trusted and Preferred Speciality Coatings Company Globally.

Mission

To provide High Quality,Customised, Cost Effective, Innovative Products and Coating Solutions using Modern Cutting Edge Technology with Relentless, Distinctive and Prompt Services.

Values

Deep beneath our strong products lies our sincerity, our hard work, our pledge and a responsibility that we will manufacture products that give every rupee spent its value. With our value systems in place, we are true to our belief to write, “We make you look good”.

Research & Development (R&D)

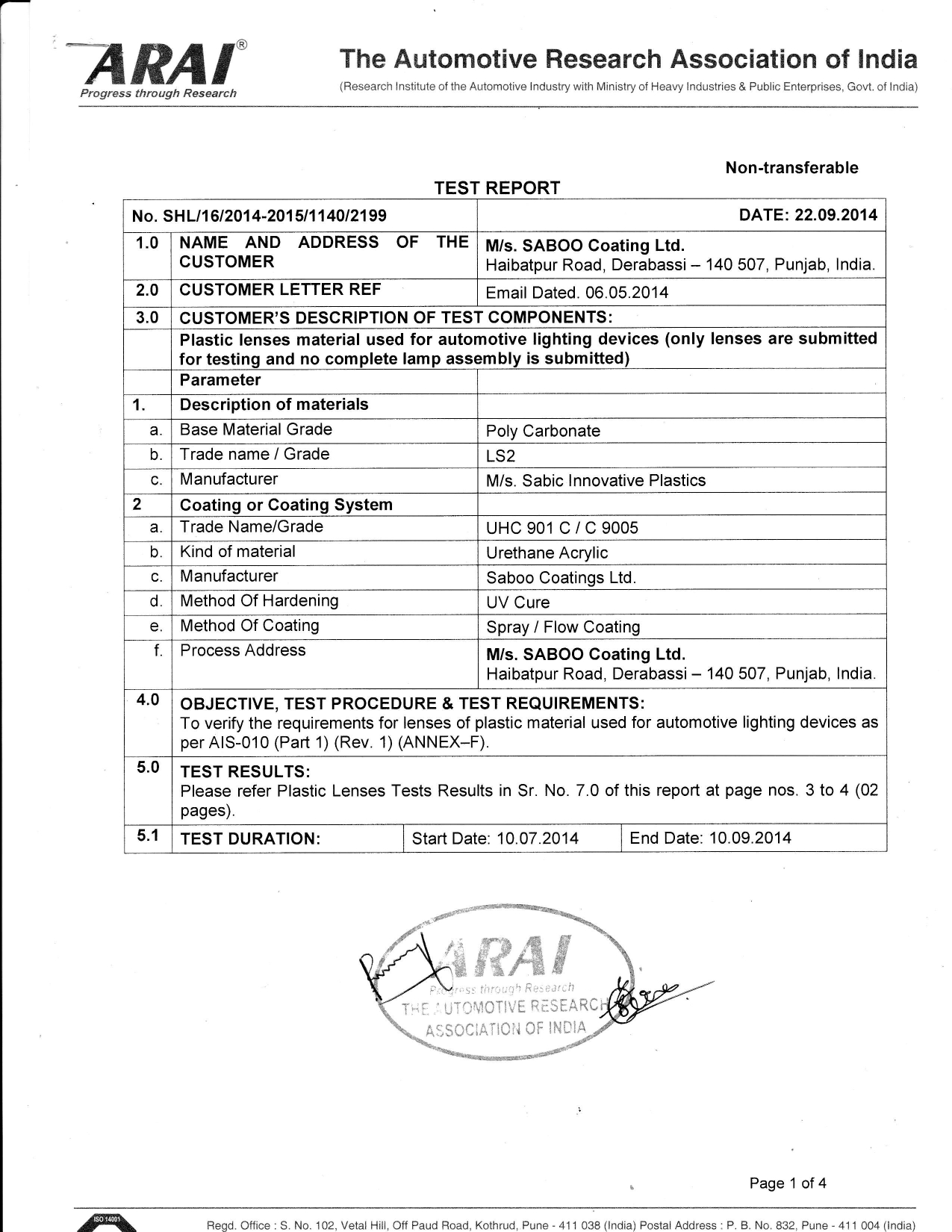

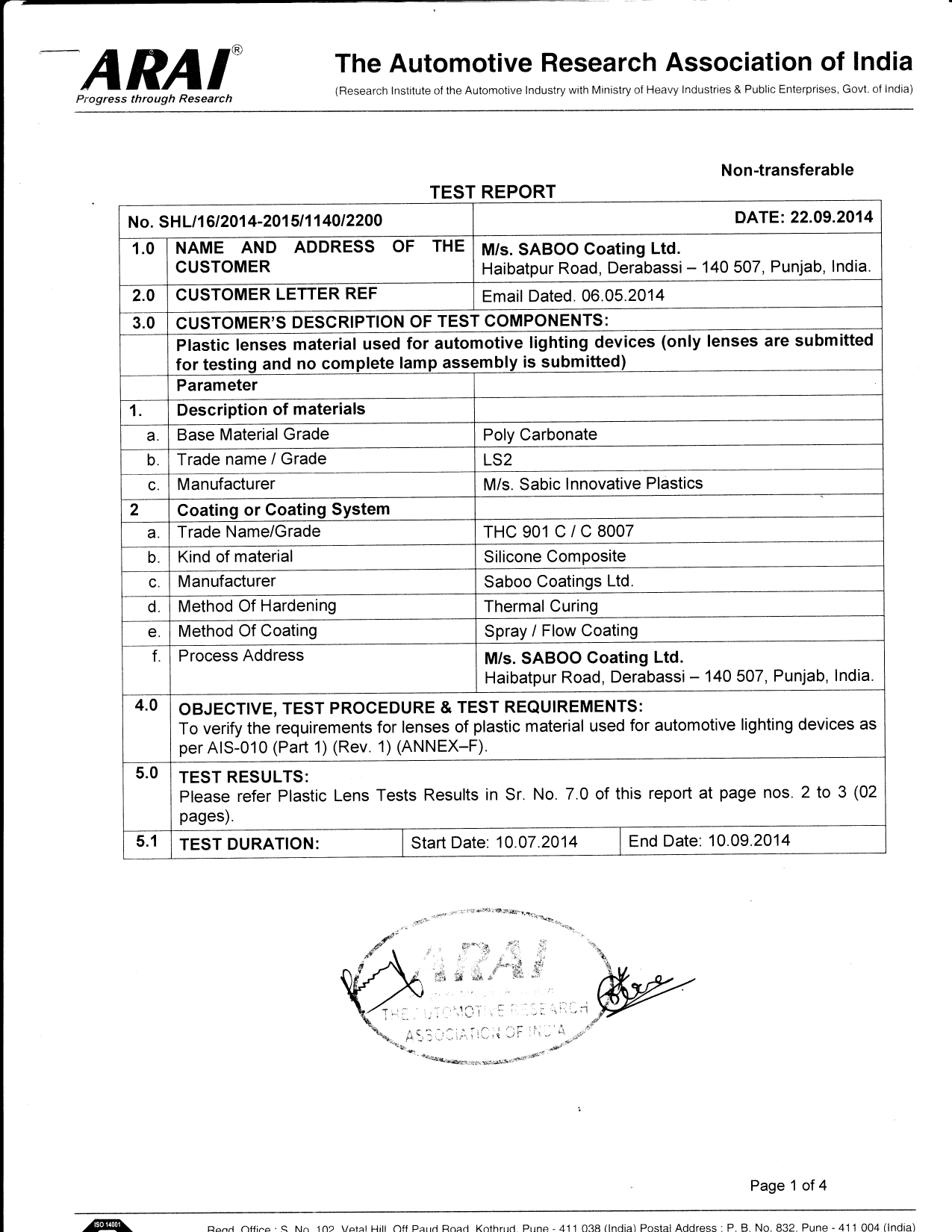

SBL Specialty Coatings (formerly Saboo Coatings ) has a world-class research and development infrastructure, dedicated to the continuous optimization of our existing products for cost efficiency and quality, as well as the development of new products based on the state of the art in coatings technology.

We have more than 20 scientists and engineers, all with a minimum bachelor’s degree in a related scientific field and experience ranging from 5 to 30 years in the field of coatings technology. They work in a dedicated air-conditioned 250 square mts R&D Facilities that is equipped with state of the art equipment including the following

- UV Metalizing M/C

- QUV Weatherometer

- Salt Spray Testing Chamber

- Hardness Testing Apparatus

- Scratch Testing M/C

- Spectrophotometer

- Fractional Distillation Appartus

- Impact Testing M/C

- UV Curing M/C

- Glossometers

- Hegmann Gauges

- Karl Fishcher Titrators

- Metal Pyknometer

- Muffle Furnace

- Ovens, pH Meters, DFT Gauge etc.

In addition to our own dedicated resources, SBL Specialty Coatings has established relationships with reputed laboratories in India and abroad to help in the development of new products. A Global Technology Advisory Board provides us regular insights and advice into new developments in the field of coatings. The combined result is a formidable R&D group supporting a strong manufacturing base and one of India’s best sales and service teams for industrial coatings. With us, you can not only have the comfort that the product we supply you is world-class, but also know that whatever custom application you might have, we’ll develop it for you.

RMQC & FQC

At SBL Specialty Coatings, there is no priority higher than assuring the quality of the products we ship to our clients. An ISO 9001:2015 certified company, we have detailed and extensive processes in place to ensure that the entire organization works in concert to assure top quality. We follow a four-step process to ensure product quality.

All raw material is sourced only from known well-established suppliers and undergoes long-term testing prior to use. Every single raw material batch received undergoes specific tests prior to acceptance. We maintain very tight tolerances on all acceptance parameters.

Each production batch undergoes testing by the Production QA group. This includes several tests, based on the chemistry and other requirements of the product being produced. Once these tests are completed the batch is handed over to the Customer Relationship Management QA team. The CRM QA team then conducts its own tests prior to accepting the batch “on behalf of our eventual clients” and readies it for dispatch.In this way, every single batch undergoes a rigorously managed production process followed by a double QA process, ensuring top, consistent quality for our clients

- Adhesion / Crosscut

- Chemical Resistance

- Computerized Color Matching

- Conductivity

- Cyclic Corrosion Test

- Drying time

- DFT

- Ethanol Dip

- Flammability Test

- Flexibility

- Freeze - Thaw Stability

- Gasoline Resistance

- Gloss at 20°/60°/80°

- Heat Resistance

- Water Immersion Resistance

- %NVM

- Heavy Metal Content Testing is outsourced to established third-party labs

Production

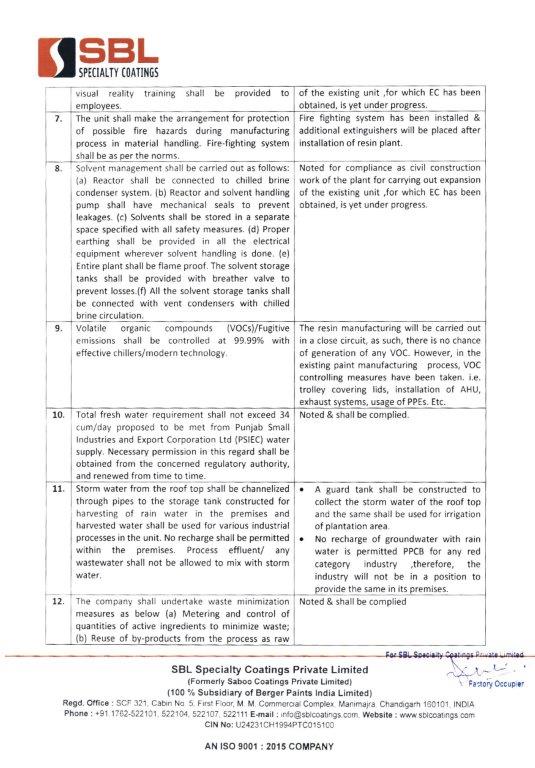

SBL Specialty Coatings (formerly Saboo Coatings) has ISO 9001:2015 certified state of the art manufacturing facilities (2 Manufcaturing Plant) with an extensible capacity of apprxomately 25 KL/day and equipped with latest techonologies for the manufacture of liquid coatings products. We have stringent quality control processes that assure a first-time acceptance of ~99%. Our Facilities is protected by an extensive fire management system and full back-up generators provide for uninterrupted production in the event of power failures.

In addition, we have an In-house resin production faciliy to produce acrylic and alykd resins with more than adequate capacity to fulfill of our internal consumption needs, today and in the future. These resin plants allow us to create customized and cost effective resins that in turn allows us to create optimized product formulations and assure batch to batch uniformity.

- Attritors

- Bead Mills

- High Speed Disperser

- Mixers

- PUG Mill

- Sand Mill

- Extensive measuring and calibration machinery

- Computerized testing equipment

- Underground solvent storage with automatic pump dispensation.

SBL Specialty Coatings is also engaged in contract manufacturing for other Industrial Coatings Manufacturers. The Facilities is situated on chandigarh Delhi highway for easy connectivity with all places.